VALVES MANUFACTURING

Presentation

Building on an exceptional installed base, FCT has created a bespoke business model to deliver precision valve replacement.

FCT retains full ownership of the valve design and proprietary know-how, while the manufacturing process is subcontracted to approved manufacturing partners based in France and Italy.

This approach enables us to maintain a high production capacity while ensuring the same quality standards our customers have always relied upon, thanks to the active involvement of FCT experts at every stage of production.

From 3D models and detailed drawings to material specifications, quality plans, and customer-specific requirements, all steps are carefully designed, controlled, and documented by FCT engineers. In addition, FCT technicians are present at partners’ manufacturing facilities during assembly and testing to ensure the product meets the expected performance criteria.

Key advantages

– Guaranteed identical, high-quality valves with proven performance –

– Reduced costs for end-users thanks to optimized engineering and replacement processes –

– Optimized spare parts and stock management –

Valves design & Technical features

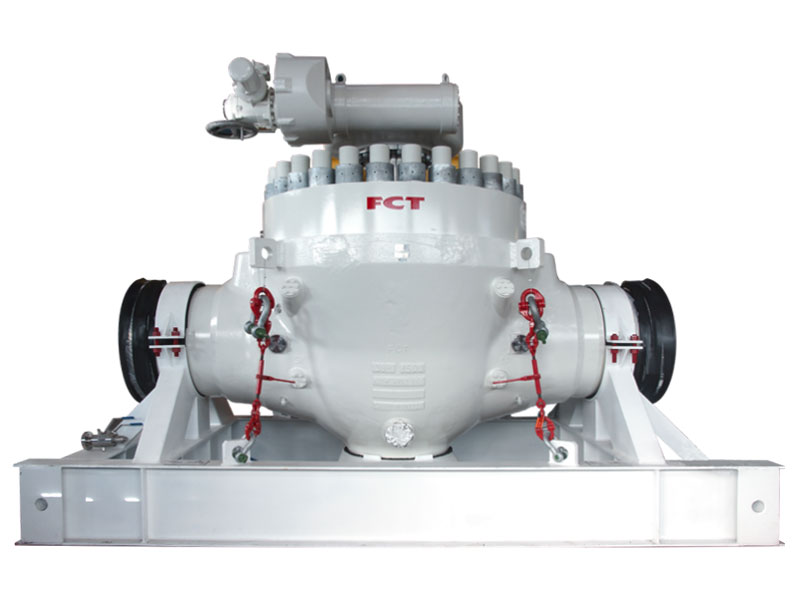

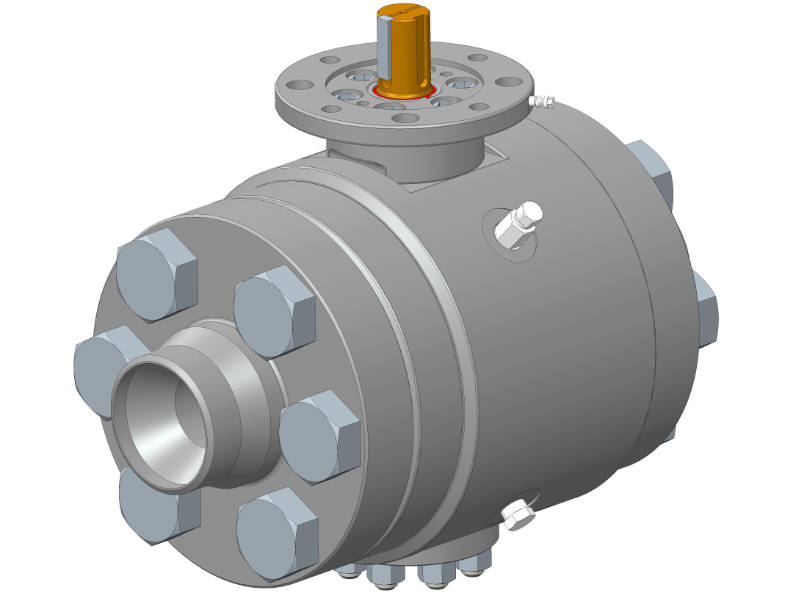

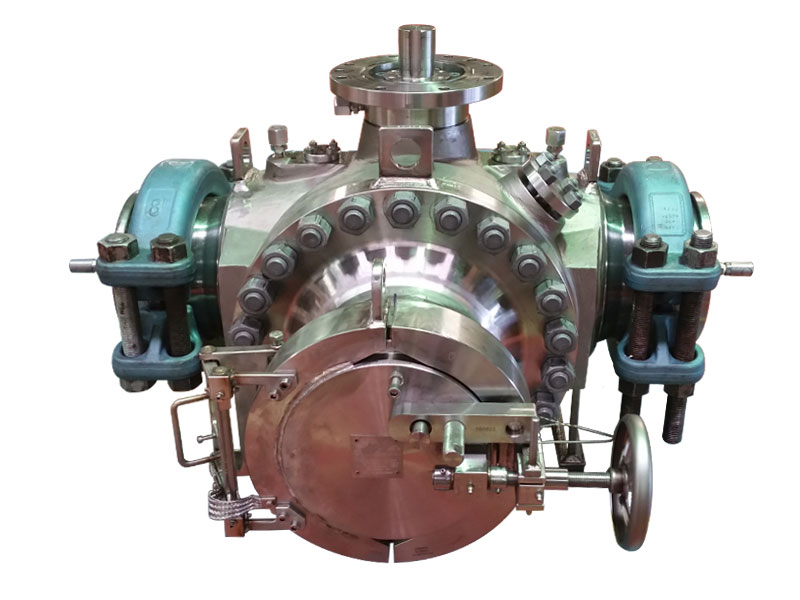

SPLIT BODY / SIDE ENTRY VALVE

Split Body / Side Entry Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 2500

- API 6A API 3000 – API 15000

- -101°C (depending on applicable international standard & Specification) / +400°C

Main characteristics

- Trunnion Mounted

- 2 or 3 pieces

- Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

- Double block and bleed capability

- SIL 3 Compliant

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

- SPE (Self relieving) & DPE

Additional data

- Product used in a wide range of application from upstream to downstream sector in Oil & Gas, petrochemical and process.

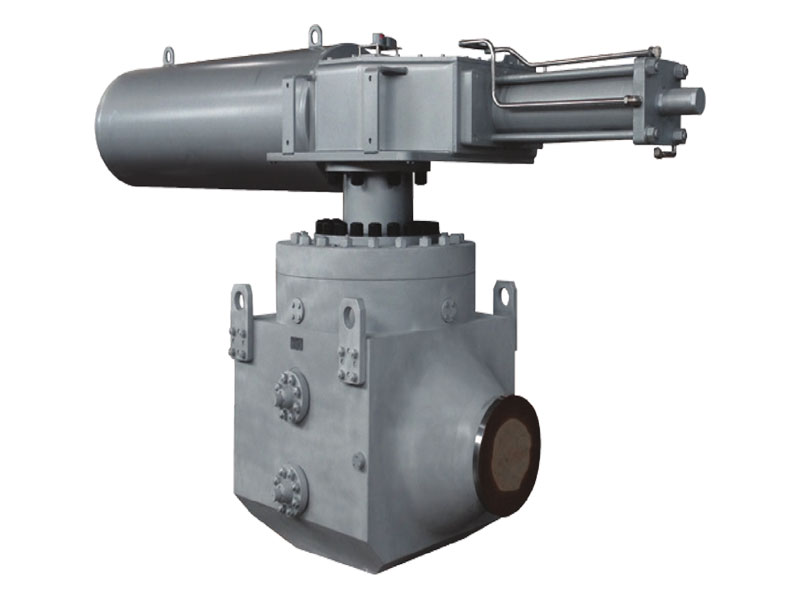

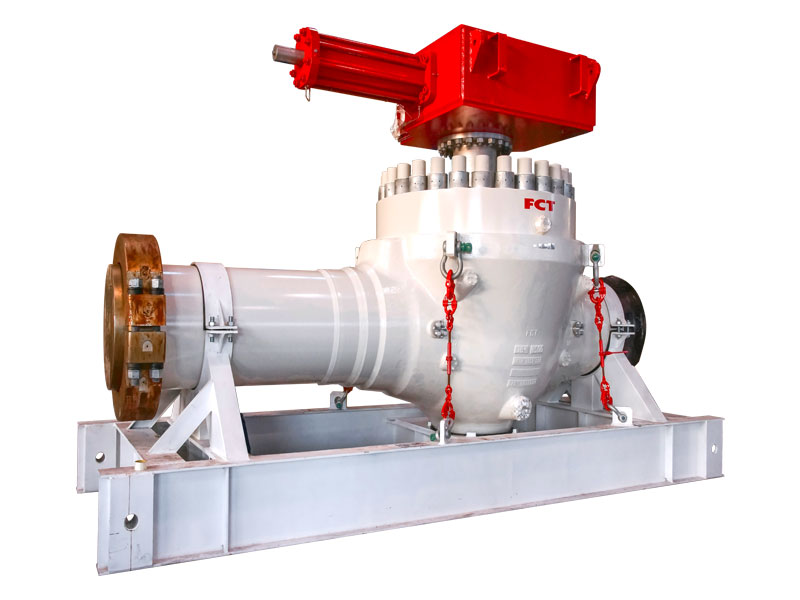

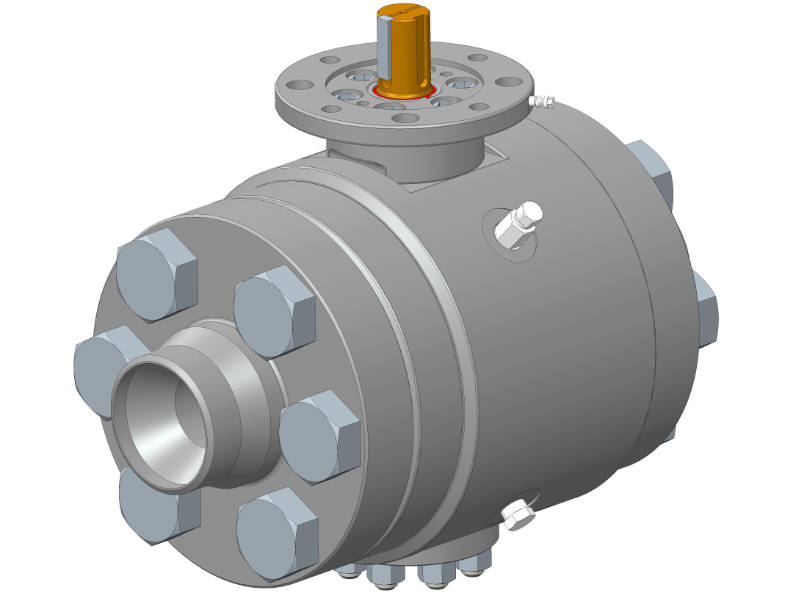

TOP ENTRY VALVE

Top Entry Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 2500

- API 6A API 3000 – API 20000

- -101°C (depending on applicable international standard & Specification) / +400°C

Main characteristics

- Trunnion Mounted

- Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

- Double block and bleed capability

- SIL 3 Compliant

Body / Trim Material

- Forged or Cast

From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

- SPE (Self relieving) & DPE& DPE

Additional data

- Thanks to the very strong design, Top entry products are generally used for severe services such as Riser, High pressure (API6A) or HIPPS and great behavior in front of pipe loading. The main advantage of this design is inline maintenance, no need to dismantle the valve from the line.

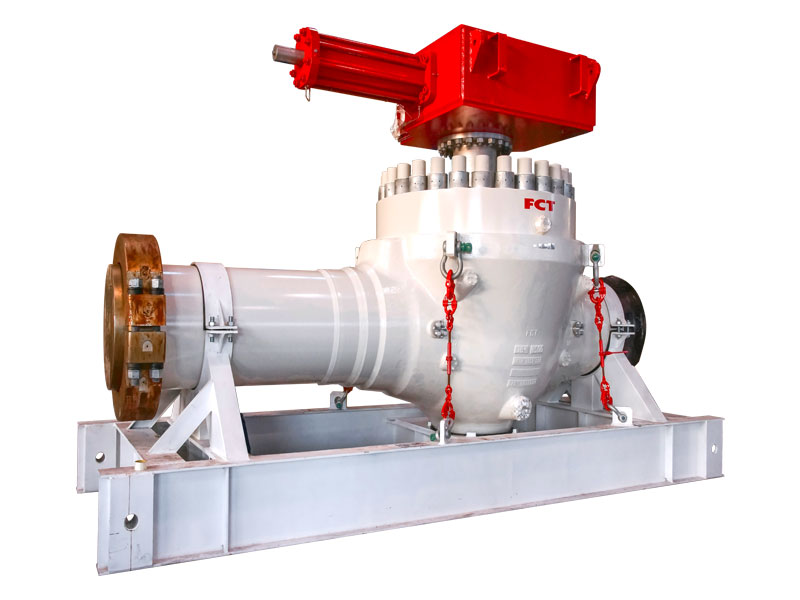

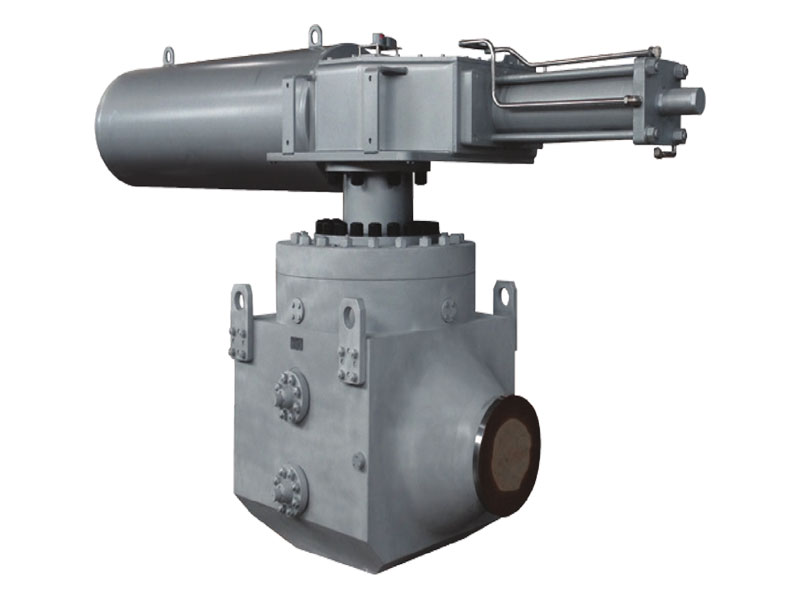

API6A VALVE

API6A Valve

Specifications:

Size / Pressure range / Temperature

- DN 50-DN500

- API 6A API 3000 – API 20000

- -101°C / +200°C

Main characteristics

- Trunnion Mounted

- Split Body/Side Entry or Top Entry

- Flanges RTJ, WE, Hub (clamp), Compact flanges

- Double block and bleed capability

- SIL 3 Compliant

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

- SPE (Self relieving) & DPE

Additional data

- HP/HT fully customized design to work on the most extreme upstream applications.

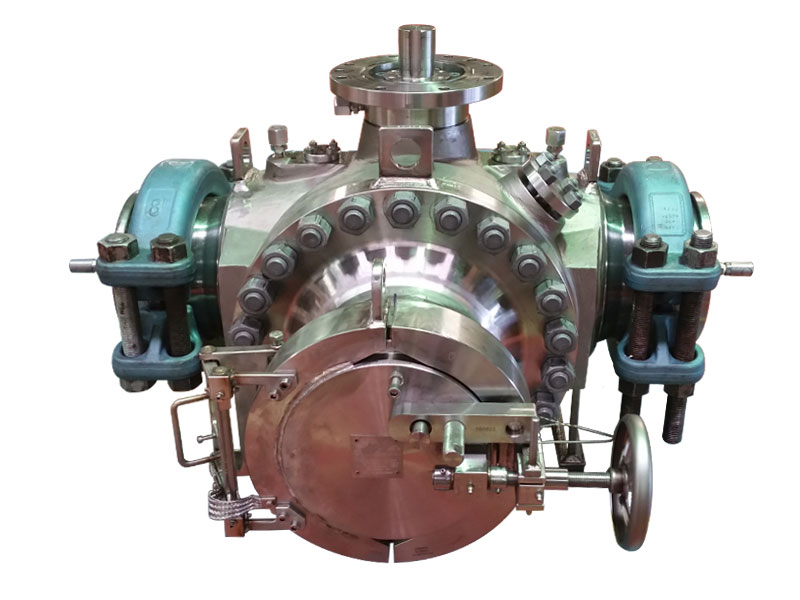

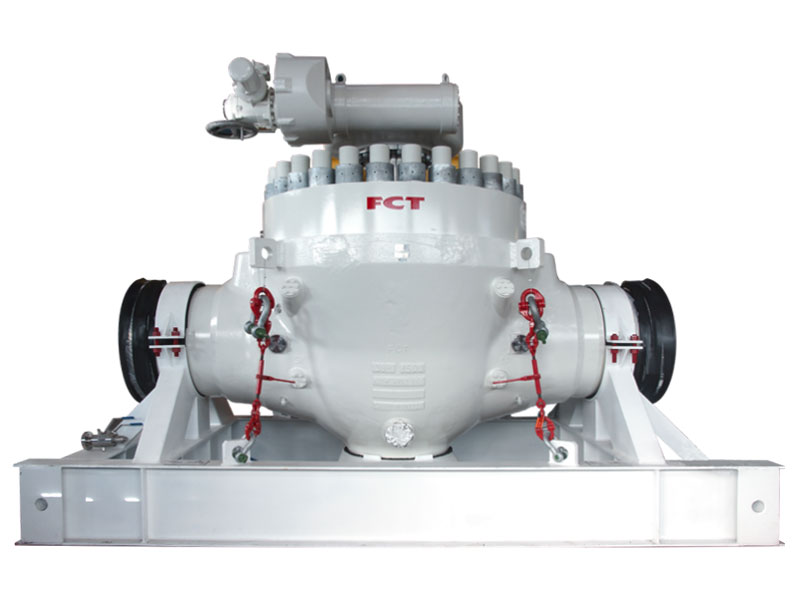

TANDEM DBB VALVE

Tandem DBB Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 2500

- API 6A API 3000 – API 15000

- -46°C / +200°C

Main characteristics

- Trunnion Mounted

- Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

- Double Isolation & Bleed as per API 6D (type A) new requirement H12.

- SIL 3 Compliant

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

- SPE (Self relieving) & DPE

Additional data

- Customized Two balls & four seats in one body to ensure a perfect isolation from a single or two pressure sources in a compact solution.

DIB VALVE

DIB Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 2500

- -46°C / +200°C

Main characteristics

-

Trunnion Mounted

-

Split Body/Side Entry or Top Entry

-

Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

-

Double Isolation & Bleed as per API 6D (type B) new requirement H12.

-

SIL 3 Compliant

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

- SPE (Self relieving) & DPEE

Additional data

- Fully customized single valve for perfect isolation against a single pressure source (Double Isolation and Bleed) allowing 100% safe line opening. Typically used for pig launcher/receiver isolation. Range qualified by Equinor up to 38″ 1500#.

SUBSEA VALVE

Subsea Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 2500

- API 6A API 3000 – API 15000

- -46°C / +200°C

- Shallow Water

Main characteristics

- Trunnion Mounted

- Split Body/Side Entry or Top Entry

- Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

- Double block and bleed capability

- SIL 3 Compliant

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

- SPE (Self relieving) & DPE

Additional data

- Reliable design to ensure a long life time and prevent extremely difficult and costly maintenance.

HIPPS VALVE

HIPPS Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 2500

- API 6A API 3000 – API 20000

- -101°C / +400°C

Main characteristics

-

Trunnion Mounted

-

Split Body/Side Entry or Top Entry

-

Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

-

Double block and bleed capability

-

SIL 3 Compliant

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

- SPE (Self relieving) & DPE

Additional data

- Valves for High Integrity Pressure Protection System, SIL 3 compliant. The last safety barrier protecting the downstream equipments by isolating from the upstream overpressure.

PIG LAUNCHER / RECEIVER VALVE

PIG Launcher Receiver Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 1500

- -46°C / +200°C

Main characteristics

- Trunnion Mounted

- Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

- Block & Bleed

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

Additional data

- FCT Pig Launcher/Receiver compact solution, allowing a PIG length of 1,4 X the inside diameter of the pipe.

- Perfect compact and cheap solution (compare to conventional PIG Launcher/Receiver) dedicated to non dangerous application.

HIGH TEMPERATURE VALVE

High Temperature Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 2500

- API 6A API 3000 – API 10000

- Up to+ 400°C

Main characteristics

- Trunnion Mounted

- Split Body/Side Entry or Top Entry

-

Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

-

Double Block & Bleed capability

-

SIL 3 Compliant

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Metal seated

- SPE (Self relieving) & DPE

COMPACT VALVE

Compact Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN300

- Usually from 2″ to 4″

- ASME Class 150 – 2500

- API 6A API 3000 – API 15000

- Usually pressure class 1500#, 2500# and API 10000

- -46°C / +200°C

Main characteristics

- Trunnion Mounted

- Split Body/Side Entry

- WE Swivel

- Double block and bleed capability

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

- SPE (Self relieving) & DPE

Additional data

- The smaller face to face dimension of the compact design is allowing customer to reduce drastically the size of their system layout or skid. The swivel flanges also allow a very easy installation and valve replacement.

3 & 4 WAYS VALVE

3 & 4 Ways Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 2500

- -46°C / +200°C

Main characteristics

- Trunnion Mounted

- Split Body/Side Entry & Top Entry

- Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

LOW TEMPERATURE VALVE

Low Temperature Valve

Specifications:

Size / Pressure range / Temperature

- DN 50 – DN1500

- ASME Class 150 – 2500

- API 6A API 3000 – API 10000

- Down to -101°C (depending on applicable international standard & Specification)

Main characteristics

-

- Trunnion Mounted

- Split Body/Side Entry or Top Entry

- Flanges RF, RTJ, WE, Hub (clamp), Compact flanges

- Double Block & Bleed capability

- SIL 3 Compliant

Body / Trim Material

- Forged or Cast

- From carbon steel up to most exotic material such as SS, DX, SDX 6MO, Alloy 625, Monel, Titanium, …

Seats

- Soft seated & Metal seated (Tungsten Carbide from 150µm to 400µm)

- SPE (Self relieving) & DPE

Get In Touch

+33 9 78 81 06 41

Location

Avenue Escadrille Normandie Niemen

ZAC Empallières

13730 Saint-Victoret

France

Opening Hours

Mon-Fri: 8:30-12pm — 13:30-17:00

Sat-Sun: Closed